Are You Experiencing Any of These Common “Filtering” Issues?

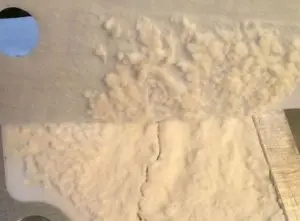

Cake Sticking to the Filter Cloths

This can cause excessive time to discharge the filter cake. Debris causing more frequent filter cloth washing can lead to the need to change the cloths more often.

Poor Filtrate and/or Filter Cake Quality

Poor filtrate can cause non-compliance with local water authorities. If the filtrate is the product, this can cause issues requiring additional filtration. Poor cake solids (too much moisture) can also cause the cake to stick to the cloths, increasing disposal costs. If the cake is a product, this condition may require extra time for drying.

Cake Build-Up Inside the Feed Port (Core) of the Filter Plate

Excess core buildup slows the cake discharging process, as each filter plate core will need to be cleaned prior to shifting the next plate (even if the filter cake discharges completely). If not properly cleaned, this can lead to filtration issues on the next filtration cycle.

Holes Developing in the Filter Cloths

Holes cause the effluent to be cloudy and can cause filtration time to become extended.

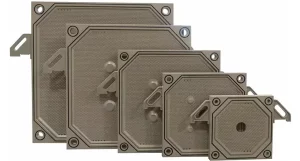

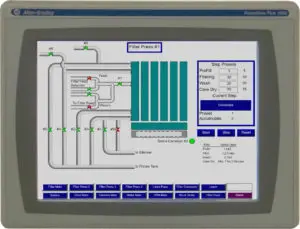

M.W. Watermark® is Your Go-To Resource for Filter Press Solutions

M.W. Watermark can help you resolve these filter press “filtering” issues and others as well.

In addition to manufacturing custom filter cloths, M.W. Watermark also designs, manufactures and services industrial filtration equipment including filter presses, clarifiers and more.

M.W. Watermark’s Sales and Service Team members have the upfront knowledge to determine if your issue can be resolved by simply changing the type of filter cloth fabric being used, or if there is also a mechanical or chemical solution that should be implemented.

We pride ourselves on being able to solve the problem in a manner that works best for the customer.

Potential Filter Cloth Solutions / Troubleshooting Options

Air Permeability Testing

In our dewaterability laboratory, we can test your cloth both as received, and then after a pressure or chemical wash, to determine blinding solutions.

Your Filter Cloth Material May Need Changing

Polypropylene has become a popular fabric for the majority of filter press applications due to its high strength and excellent resistance to most acids and alkalis. However, there are now alternative fabric choices to help with especially challenging slurries, such as those that are highly abrasive.

For example, polyamide (nylon) offers a unique non-blinding, abrasion resistant and hydrophobic alternative to the conventional polypropylene and polyester fabrics, and may be more appropriate for certain applications.

In many cases, this fabric will last longer and require less cleaning – thus increasing the efficiency of the filter press operation.

We also offer highly calendared polypropylene cloths that offer similar benefits.

Fabric Permeability

Depending on the application, we can offer the best fabric permeability to maximize filtration efficiency.

Our fabrics range in permeability from .1 cfm to 100 cfm.

Weight of the Fabric

The weight of the fabric is typically proportional to its strength, which in turn affects the life of the filter cloth.

Larger equipment tends to require heavier weight fabrics.

Our range is 9 oz./sq. yd. to 20 oz./sq. yd. This range covers most filter press requirements.

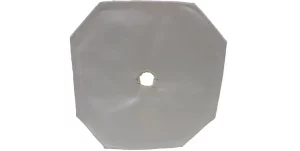

Construction of the Filter Cloths

Filter cloth construction can be modified to better solve the issue at hand.

This can include the addition of hook and loop material to the top and/or side of the cloths for a better fit.

Addition of Rubber Barrel Necks

Rubber barrel necks are sometimes needed in the center of the pull-through to stop filtration in this area from occurring – and to offer better abrasion resistance.

Contact M.W. Watermark to discuss your filter press “filtering” challenges with our Sales and Service Team.

About M.W. Watermark

M.W. WATERMARK wants to make a difference. We are passionate about the world’s water. We are innovative, focused on customer service and always try to exceed expectations. We are an environmentally conscious company with people who are energized, encouraged and inspired to make a difference on our planet by helping to keep our shared, finite water supply clean and usable for generations to come. We build amazing, custom water and wastewater treatment equipment. Together, we can make a difference.

© 2024 M.W. Watermark, L.L.C.

M.W. Watermark, LLC. M.W. Watermark® is a federally registered and protected trademark owned by M.W. Watermark, L.L.C. All rights reserved