Slant Plate Clarifier (SPC)

M.W. Watermark® slant plate clarifiers, also known as inclined plate clarifiers, are engineered to provide efficient solids removal from a wide range of waste and process streams.

- Description

- FAQ’s

- Photos

The M.W. Watermark Slant Plate Clarifier (SPC)

Our slant plate wastewater clarifier is one of the most efficient methods available for the removal of solids from process liquid and waste. While there exists a variety of designs for such devices, utilizing inclined plates allows us to pack the widest possible combined plate area into a compact floor space. Plates are placed close together, and settling surfaces are stacked to form a settling area 10 times larger than the total area occupied by the machine.SLANT PLATE CLARIFIER PRODUCT FEATURES

Within our range of slant plate clarifiers, we offer nine standard-sized models, handling between 5 and 400 GPM, a sludge holding capacity between 17 and 960 gallons, and a plate area of between 16 and 1,680 square feet. That large capacity comes at very little cost in terms of floor space; sizes range from 45″ x 23″ to 170″ x 120″, with heights ranging from 51″ to 147″. The machines feature no moving parts, constructed using 1/4″ steel and dye penetranted tested welding. Integral flash mixing and flocculation tanks help to increase efficiency, and the entire structure is sandblasted, primed, and painted to provide maximum chemical resistance. Stainless steel models are also available for enhanced corrosion resistance. Each device comes equipped with 1/4″ thick removable PVC settling plates, dual sludge outlet flanges, sludge sampling ports, and a large side-access hatch to allow for easy maintenance.

AVAILABLE OPTIONS

In addition to the standard features, our slant plate clarifiers can also be equipped with:

- Mixers for flash and flocculation tanks.

- Coal-tar epoxy interior coating (other coatings and materials are available).

- Influent feed and sludge discharge pumps.

- Custom designs available.

SIZES OFFERED

For specifications and drawings of our models, click the appropriate link.

For more information check out our SLANT PLATE CLARIFIER Brochure or contact the M.W. Watermark Filtration Experts.

Q: What are the advantages of using a slant plate clarifier?

Inclined plates allows settling area to be up to ten times more than floor space occupied by the SPC

- The lack of moving parts translates into a lower chance of mechanical failure

- Energy cost savings

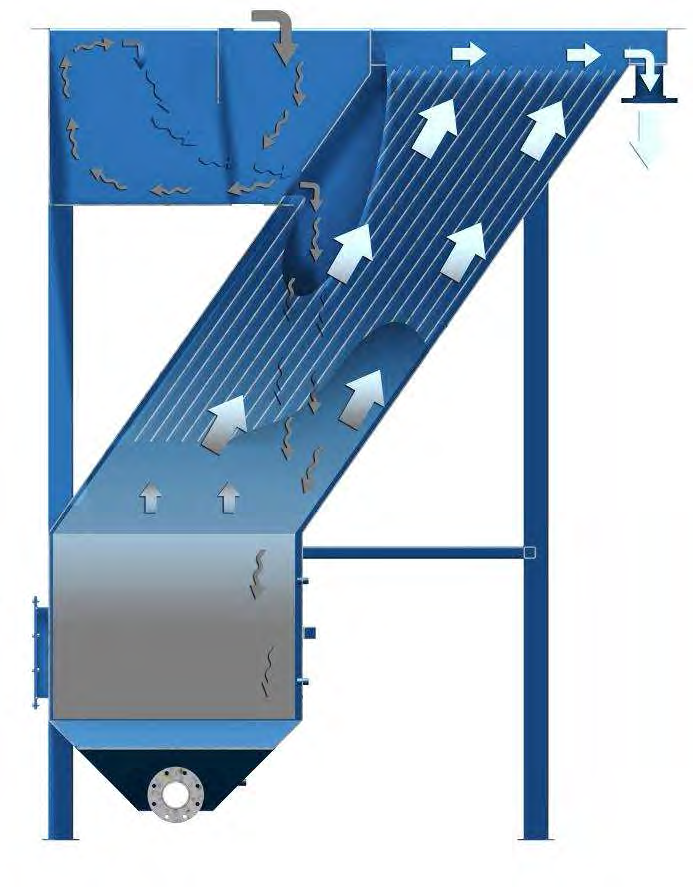

Q: How does a slant plate clarifier work?

- Influent wastewater is fed into the top of the clarifier.

- The liquid flows downward through the feed channel to the sludge chamber below the inclined plate stacks.

- The fluid then enters the bottom of the inclined plate stacks and flows between the settling plates.

- As solids settle along the plate surfaces, clarified liquid flows upward, over weirs, and into a trough.

- Clarified effluent is then discharged from a connection at the bottom of the trough.

- Sludge is periodically drawn off the bottom of the sludge chamber at the bottom of the clarifier.

For a more detailed explanation of how a slant plate clarifier works, click on the thumbnail below to view our informative brochure: