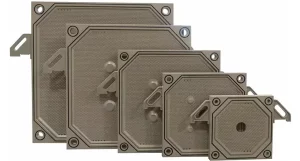

Filter plates are among the most important components of a filter press. To maintain peak levels of efficiency and avoid failure, the plates need to be inspected regularly for signs of wear or damage. To help you evaluate the state of your plates, M.W. Watermark® offers some advice below. If you have any questions about a specific model or problem, contact one of our factory-trained service technicians for personalized assistance.

Identifying Potential Problems

In industrial settings, filter plates have to work through highly demanding conditions. While they’re designed to withstand high pressure and large volumes, over time, breakage and malfunctions can occur. When evaluating your filter press plates, one of the first things to look for is if they’re clean. They need to be cleaned thoroughly on all sides, especially the bottoms, and frequently, as dirty plates can cause inefficiencies and even catastrophic sidebar failure.

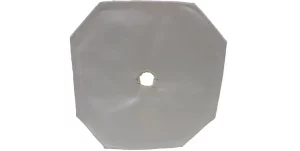

Next, you’ll want to check the components. If everything looks good and appears to be functioning properly, then no further action is required. Some of the most common part failures include the filter cloth and gasket. Filter cloths are prone to holes caused by abrasive sand, gravel and other particles. When holes appear, the aggregate flowing into the discharge can wear down the plastic on the discharge eyes of the plates.

Leaking is another common concern with filter plates. Some types of plates, like CGR (Caulked, Gasketed, Recessed Chamber) plates are designed to be virtually leak-proof. So if you spot some dripping, it could be a sign repairs are needed. With other types of plates, however, a little leakage may be normal.

Addressing the Issues

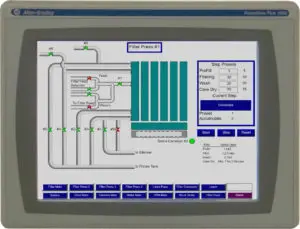

If you find that your filter plates are no longer performing at their peak condition, turn to M.W. Watermark for help. Not only do we supply maintenance and installation tools to perform repairs, but we also offer free video tutorials for some common “how to” topics. As always, we have factory-trained service technicians on standby to offer advice.

Additionally, if you need to replace your filter plates, we keep a large stock of polypropylene plates in-house and ready to ship, so you don’t have to worry about downtime. Or, you’re welcome to put in a custom request for specific dimensions or configurations.

Get Back Up and Running

If you have any questions about evaluating the condition of your filter plates or would like a quote, contact the team at M.W. Watermark today.

About M.W. Watermark

M.W. WATERMARK wants to make a difference. We are passionate about the world’s water. We are innovative, focused on customer service and always try to exceed expectations. We are an environmentally conscious company with people who are energized, encouraged and inspired to make a difference on our planet by helping to keep our shared, finite water supply clean and usable for generations to come. We build amazing, custom water and wastewater treatment equipment. Together, we can make a difference.