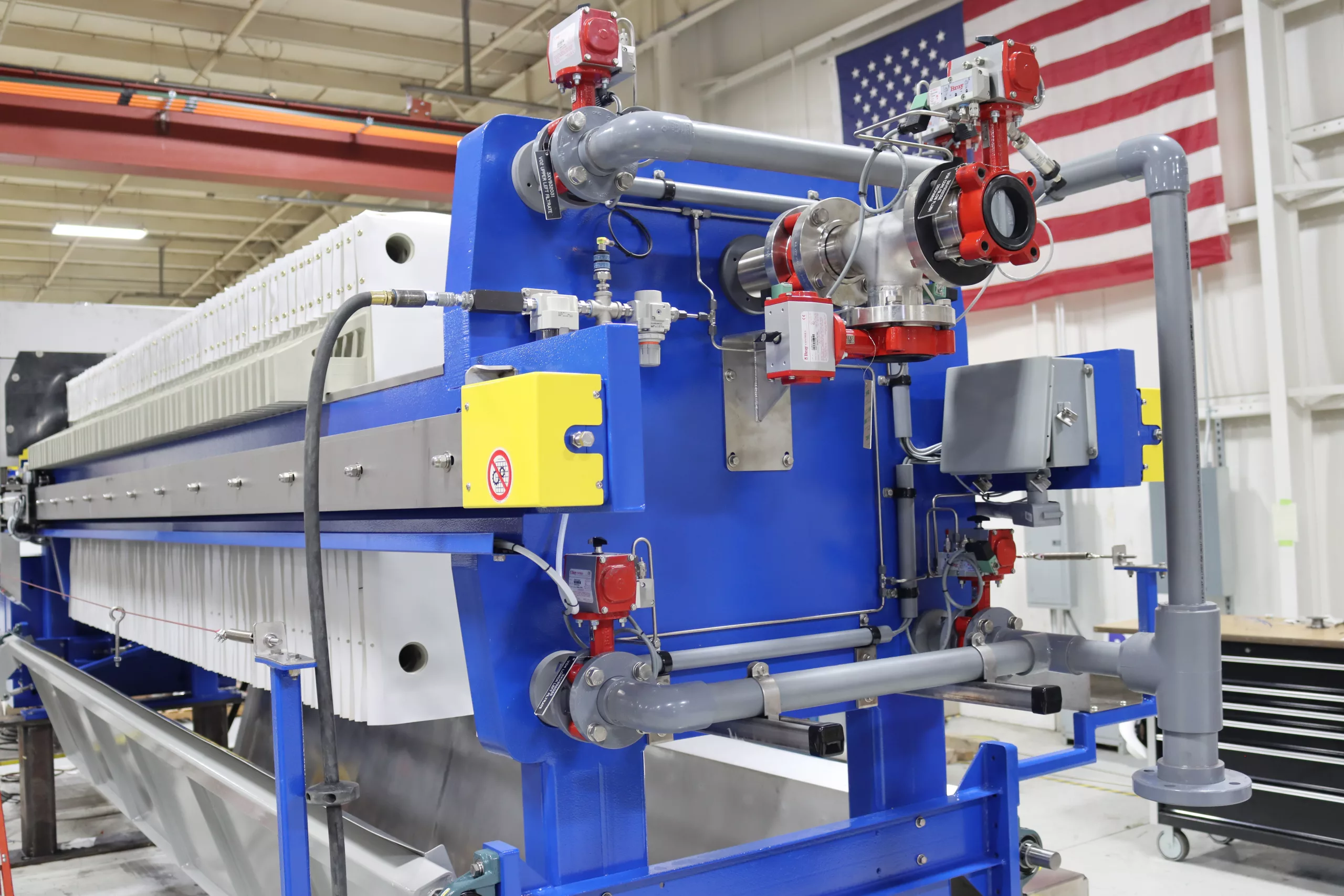

Bioplastics, derived from biopolymers or bio-based polymers, are gaining traction as a sustainable solution in the commercial plastic life cycle within a circular economy. This approach emphasizes using renewable or recycled raw materials, deploying carbon-neutral energy in production, and ensuring end-of-life product reuse or recycling. Filter presses are commonly used to separate key materials in the production process of bioplastics.

Growing consumer awareness and demand for sustainable products have led to increased research and innovation in bioplastics technology. Today, bioplastics are being increasingly used as alternatives to conventional plastics in various applications, including packaging, disposable items, textiles, and automotive parts, as part of efforts to reduce dependence on fossil fuels and mitigate environmental pollution.

- Filter presses and filter cloths designed for bioplastics production

- Materials selected to meet specific process conditions

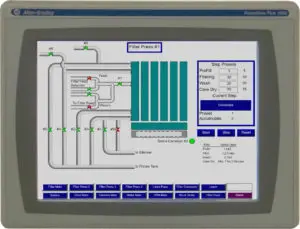

- Testing services to aid with process design

- Leak-proof plates for bioplastics production

- Spare parts and filter cloths for most makes and models of filter presses

- Services to help ensure a smooth installation of new equipment and maintain existing equipment