Filter presses need regular maintenance to continue operating at optimal performance levels. An important part of this care is servicing the filter cloths.

As the initial barrier that removes solids from liquid in the filtration process, filter cloths experience a great deal of wear and tear. It’s important that they stay porous to achieve good filtration rates. When fine particles become lodged deep within the fabric, filtration rates can become compromised. Cleaning must be done on a regular basis to maintain full functionality of the filter press.

Filter cloth life can be shortened by certain chemicals in the slurry, mechanical wear, abrasion and blinding. Mechanical wear can be reduced by using a more durable cloth. Blinding (clogging of the cloths) often comes from “slamming” sludge into the press.

PREVENTATIVE MEASURES

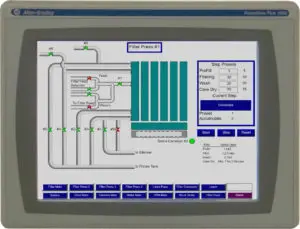

Automatic Feed Pump Control System (AFPCS)

Consider an Automatic Feed Pump Control System (AFPCS) to automatically and gradually increase pump pressure during the filtration cycle. High initial feed pump pressures can build a tightly packed layer of solids on the filter cloth. By reducing the initial feed pressure, a soft layer of slurry particles can be deposited on the cloth. Because this layer then becomes the filtering media, the filterability of the incoming slurry is enhanced.

An AFPCS can be retrofit to any filter press. Learn more about how an AFPCS allows your filter press to run at its optimum efficiency.

M.W. Watermark Filter Press with an AFPCS

Pre-Coat

Pre-coat material is any porous substance that allows liquid to pass through. The substance should be fine enough to mix with water but not so fine as to be impassable. It is the gaps within the substance that will provide much of the actual filtration.

“Pre-coating” a filter press with perlite, diatomaceous earth or similar products can also add substantial life to cloths. This coating protects against wear and minimizes blinding.

Learn more about pre-coat and how it is applied in a filter press.

Perlite can be used as an effective filter press pre-coat

Cloth Additions

If your filter cloths are wearing out prematurely at the center feed, a latex-reinforced cloth barrel neck can help. In cases of an especially high amount of abrasion at the neck, a rubber barrel neck can help protect that area.

Non-Gasketed (NG) filter cloths with a latex-reinforced cloth barrel neck

Rubber barrel neck

CLEANING METHODS

Using a Pressure Sprayer

When filtration cycles become too long or the initial filtration pressure is too high, it’s time to clean the cloths. One of the easiest ways to accomplish this is by using a portable cold water pressure sprayer, as the plates do not need to be removed from the filter press. However, care must be taken when using a pressure sprayer to ensure that the cloths are not damaged. By using a fan-shaped spray pattern and staying back a few feet from the surface, the cleaning process can be accomplished without accidentally cutting the cloths. Keeping the spray pressure under 1,000 PSI is recommended as well.

ACID WASH AS AN OPTION FOR SPECIALIZED APPLICATIONS

When working with sludge from metal finishing, or a lime-based slurry where even the best-matched cloths can blind after a short period of time, the most practical method of cleaning your cloths without removing them from the press may be acid washing. Note: Acid washing is only an option if the chemistry of the sludge is reversible. Therefore, acid washing is not effective in situations that include laundry, food waste, and biological applications.

The preferred choice for an acid wash cleaning solution is hydrochloric (muriatic) acid.

Sulfuric acid is not recommended if calcium is present, as gypsum will form, permanently blinding the cloths. Nitric acid is not appropriate, as it is an oxidizing agent. Phosphoric acid is also not the ideal choice, as it is cost prohibitive. A cleaning solution that is from 5 to 10% hydrochloric acid, with the remainder being water, should be used as a starting point.

Cloths made of polypropylene can be safely cleaned in hydrochloric acid. This type of cloth material can handle a variety of acidic cleaning solutions. However, cloths made of other materials, such as nylon, should not be exposed to very low pH levels.

The process of cleaning filter cloths using acid wash requires having a system in place that can handle this procedure, as well as several safety precautions. Please refer to your filter press operation manual if your press is already equipped with a manifold and system for cloth washing. If you are interested in learning more about filter presses with cloth washing capabilities, including acid wash, contact the M.W. Watermark® Sales and Service Team for more information.

M.W. Watermark, LLC. M.W. Watermark® is a federally registered and protected trademark owned by M.W. Watermark, L.L.C. All rights reserved.