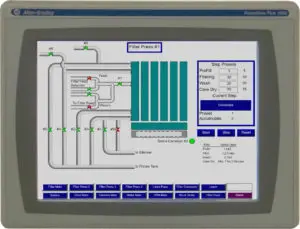

Designed for efficient solid/liquid separation, recessed chamber filter presses and filter plates are popular in a wide array of industries, from industrial and municipal wastewater to chemical processing. Learn how these types of filter presses and plates work and their advantages. Then, reach out to a member of our Sales and Service Team here at M.W. Watermark™ to see if a recessed chamber filter press is right for your application.

What Are Recessed Chamber Filter Presses and Filter Plates?

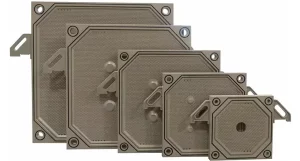

Like all filter presses, recessed chamber filter presses work by using a pressure filtration system. They have filter plates that hang on a steel frame. These plates – usually made from polypropylene – come in gasketed and non-gasketed designs.

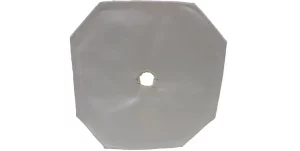

Gasketed filter plates help eliminate leaks, while non-gasketed filter plates make filter cloth installation faster since the cloths do not need to be pounded in but may result in a bit of leakage. Regardless of which type is utilized, the filter plates are clamped together in a filter press using a hydraulic cylinder and pump. Since each plate features a recessed area, when the plates are pushed together, they form a chamber in which solids collect on the filter cloths.

During the filtration process, slurry is usually fed through a large center feed hole. Liquids will pass through the filter cloth and onto the drainage surface. The liquids will eventually make their way through the discharge piping and into a process tank or drain. Meanwhile, the solids will accumulate on the filter cloths in the cavity that was formed when the plates were clamped together. Depending on the nature of the slurry, recessed chamber filter presses and plates can produce filter cakes consisting of 20 to 85 percent solids.

Click below to watch our introductory video, which illustrates the role of filter plates, filter cloths and pressure filtration in forming a dewatered filter press cake in a recessed chamber filter press.

Applications

Recessed chamber filter presses and plates are used in various industries to effectively separate liquids and solids. Some common industrial applications for this type of filter press include:

- Stone Fabrication

- Metal Finishing

- Mining & Energy

- Power

- Industrial Wastewater

- Municipal Wastewater

- Lime Softening

- Chemical Processing

- Ready Mixed Concrete

Advantages

One of the top benefits recessed chamber filter presses have to offer involves how they are fed. With a large feed hole in the center of the plate stack, the slurry is able to fill the cavities swiftly and more evenly. This helps rule out the possibility of clogging and blowing out, helping prolong the life of your plates. This is especially important in applications with high feed solids.

A second advantage comes courtesy of the plates they utilize. As previously mentioned, recessed filter plates are available in both gasketed and non-gasketed versions – and even in non-gasketed plates, there is an option for the addition of latex that runs along the edge of the filter cloth to help minimize wicking. No matter which type of recessed chamber filter plate works best for your particular application, liquids can generally be contained with proper operation.

Finally, recessed chamber filter plates make it relatively easy to empty the filter cakes. When the press is opened and the plates are shifted, the filter cakes will typically fall out from the chambers into a cake hopper or drum for simple removal. If the cakes remain in place, minor manipulation from a spatula will usually release them.

Learn More about Recessed Chamber Filter Presses/Plates

Interested in taking a deeper dive into how recessed chamber filter presses are designed and how they work? Learn more.

Contact M.W. Watermark

M.W. Watermark offers both stock and customized recessed chamber filter presses to accommodate your exact specifications. If you are in need of a recessed chamber filter press, replacement recessed chamber filter plates or other aftermarket parts and retrofits, contact us today.

About M.W. Watermark

M.W. WATERMARK wants to make a difference. We are passionate about the world’s water. We are innovative, focused on customer service and always try to exceed expectations. We are an environmentally conscious company with people who are energized, encouraged and inspired to make a difference on our planet by helping to keep our shared, finite water supply clean and usable for generations to come. We build amazing, custom water and wastewater treatment equipment. Together, we can make a difference.