Filter Cloth for Filter Presses

MW Watermark® Filter Cloths

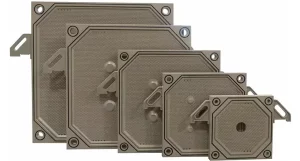

M.W. Watermark manufactures filter cloths for all makes and models of filter presses. They are sewn to the exact specifications of your filter press, guaranteeing a perfect fit. All are made in the U.S.A. in our facility in Holland, Michigan.

- Description

- FAQ’s

- Photos

- Videos

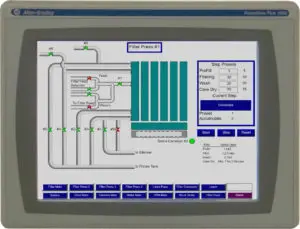

This video illustrates MW Watermark’s manufacturing processes.

MW Watermark Cloth Installation Video

FILTER CLOTH INFORMATION

When separating solids from liquids using a filter press, the very foundation lies within the filter cloth. This is the front line of the dewatering process. The cloth will separate the fine particles from the water or other type of liquid in your application, forming a filter cake. This is the deposit of solid materials left behind after the filtering process.

We offer stock cloths in various sizes for quick shipping. We can also customize to match the specifications of your filter press, providing for a perfect fit. Our fabric department maintains a large inventory of rolled goods with a wide variety of filtration characteristics allowing us to customize cloths for almost any filter press application.

FILTER CLOTH SPECIFICATION

We place the emphasis on value, which is why we offer products that keep costs down. Our products are of the highest quality, and we offer filter cloths made of the following materials: Polypropylene, Polyester, Cotton, Nylon, Polyester and Felt.

Contact our filtration experts for recommendations of which product to use for your specific needs, considering the required filtrate clarity, flow rate, and cake release of your project.

We offer cloths for the following types of plates: Gasketed, Non-Gasketed, Center-feed, Corner-feed, Membrane, and Plate and Frame.

Q: How do you select the proper fabric?

Choosing the correct fabric depends on a number of factors, including your process application, slurry composition, and the type of press you’re using. The weave, fiber type, and finishing treatments all play a role in how efficiently solids are separated from liquids. It’s important to match the material and design to your specific needs. CLICK FOR MORE INFO.

Q: How do I know when to replace the media in my filter press?

If your press is no longer producing a solid cake, or you notice a drop in pressure despite regular cleaning, it might be time for a change. Over time, particles can become deeply embedded in the fabric, reducing permeability to the point where even chemical cleaning won’t help. Likewise, if you’re seeing impurities in the filtrate or the fabric appears stretched or warped, it may be too porous to function effectively. These are strong signs that replacement is needed.

Q: How long will will they last?

Its lifespan varies based on operating conditions. Exposure to harsh chemicals, abrasive slurries, or high cycle counts can all reduce durability. Regular cleaning and routine inspections can help extend performance and avoid unplanned downtime.

To learn more, see HOW TO MAXIMIZE LIFE

Q: What’s the easiest way to reorder replacements?

M.W. Watermark® understands that when you need replacements, every day that you have to wait is costing you. That’s why we make ordering as easy and streamlined as possible, allowing you to get your operation back up and running quickly, with minimal downtime. For more info see TEMPLATE FORMS MAKE ORDERING QUICK AND EASY

Q: What are head cloths, intermediate cloths, and tail cloths?

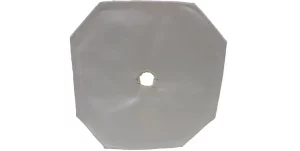

Head Cloth: Usually a single-panel cloth with a center hole, attached to the head filter plate. Other configurations include drape-over and barrel-neck cloths. (Gasketed cloth shown).

Learn more on how to install the head cloth

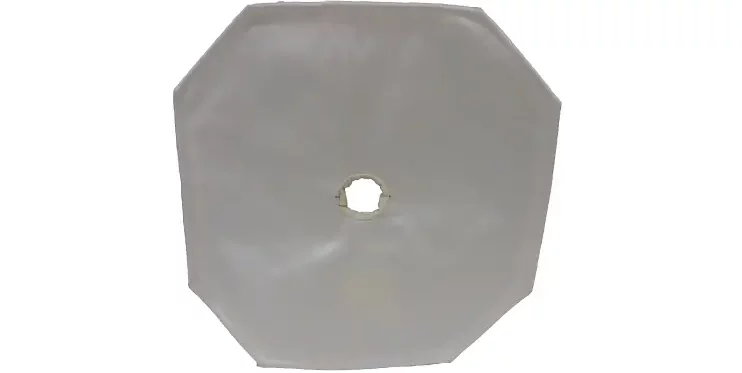

Intermediate Cloths: These constitute the majority of the cloths in the filter press and are attached to the intermediate filter plates between the head plate and the tail plate. (Gasketed cloth shown).

Tail Cloth: This is the last cloth in the plate stack – a single-panel cloth without a hole, attached to the tail filter plate, may be a drape-over cloth design. (Gasketed cloth shown).

Q: What does cloth blinding mean?

When a cloth’s porosity is hindered, and the cloth no longer allows the filtrate to flow.

Q: What is the difference between CGR and NG filter plates?

CGR vs. NG

“CGR” is an acronym for “Caulked, Gasketed, Recessed chamber.” CGR plates should provide a virtually leak-proof filter press. Cloths for these plates are octagon shaped, with a caulking rope or cord sewn into the edge of the cloth. “NG” means “Non-Gasketed.” The NG cloth is faster and simpler to install, though the tradeoff is that occasionally some dripping can happen when using NG cloths.

Q: How do you install ?

Installation depends on whether your press uses CGR (Caulked, Gasketed, Recessed Chamber) or NG (Non-Gasketed). For more info, including CGR toolkit, see options for attachment to filter plates.