Filter Plate Shifters

- Description

- FAQ’s

- Videos

SEMI-AUTOMATIC PLATE SHIFTER

The M.W. Watermark® Semi-Automatic Plate Shifter allows for easy, single-person operation of the press empty/filter cake discharge cycle. The operator positions the shifter between filter plate handles and then presses and holds the rocker switch to shift the next plate.

Semi-Automatic Plate Shifters can be easily retrofitted to many filter presses.

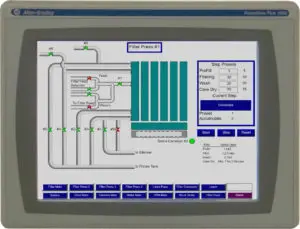

AUTOMATIC PLATE SHIFTER

An automatic plate shifter minimizes the need for operator intervention during filter cake discharge. It’s used in conjunction with the M.W. Watermark Full Automation Control System, or with custom PLC controls, to provide the highest level of filter press automation available. An automatic plate shifter is desirable when there are multiple filter presses installed in one location or where operator contact with the filter cake is undesirable. The automatic plate shifter features continuously adaptive shifting speed to optimize filter cake discharge times.Automatic Plate Shifter with “Bump Option”

In applications where the filter cake may not discharge immediately when shifting the plates due to adhesion to the filter cloth, a pneumatic “bump” mechanism is available as an attachment to the automatic plate shifter. When the bump option is included, the lift mechanism attached to the shifter carriage on one side of the filter press lifts the filter plate handle on that side of the press and drops it. The force of the filter plate handle impacting the sidebar knocks the filter cake loose from the cloth.Automatic Filter Plate Shifter (With Bump for Filter Cake Release)

Automatic Cloth Washer

Our automatic plate shifters can also be built with an automated filter cloth washer. Our design is the most compact and efficient on the market. It takes up a minimal amount of space above and around the filter press. It is designed with a variable speed drive so the cloth washer can run fast for a heavy rinse or more slowly for very soiled cloths. The washer can run up to 60 HP pumps (1500 psi) and is outfitted with 26 nozzles that clean to the edge of the filter plate.

M.W. Watermark has a team of experts in-house that can work with you to design the best material handling system for your application. Contact us today to learn more.

Q: Can a filter plate shifter be added to an existing filter press?

MW Watermark offers retrofit semi-automatic filter plate shifters for most filter presses, regardless of brand, and retrofit automatic shifters for MW Watermark filter presses with 800mm, or larger, filter plates.

Q: Are there any safety options available for the semi-automatic plate shifter?

Two handed operation is now standard equipment. Additional guarding is available. Contact us for more information.

The following video explains MW Watermark’s two handed safety interlock system:

Automatic Plate Shifter with Two-Hand Safety Interlock (Button and Switch)