Filter Presses Role in Industrial Filtration

Filter presses play a critical role in industrial filtration by separating solids from liquids in a wide range of wastewater and process applications. In industrial environments, effective filtration improves water reuse, reduces disposal costs, and supports environmental compliance. A filter press applies pressure to slurry, forcing liquid through filter cloths while capturing solids as a compact filter cake.

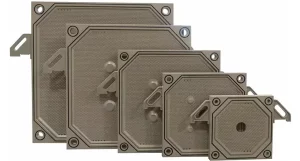

Industrial filtration systems using filter presses are valued for their efficiency, reliability, and ability to handle high solids loading. From manufacturing and metal finishing to mining, chemical processing, and industrial wastewater treatment, filter presses deliver consistent results across demanding conditions. Proper plate design, cloth selection, and operating pressure directly influence performance, cake dryness, and cycle time.

By understanding how a filter press works within an industrial filtration system, operators can improve throughput, lower operating costs, and extend equipment life.

Understanding Filter Press Filtration Technology

As sustainable water treatment becomes more important, filter press filtration delivers efficient results. Filter presses separate liquids from solids using pressure filtration. Because of this, they support many industries and treatment goals. Common uses include municipal water treatment, industrial wastewater management, food processing and pharmaceutical production.

When you understand filter press operation, you can reduce costs and also improve environmental compliance through reliable pressure filtration.

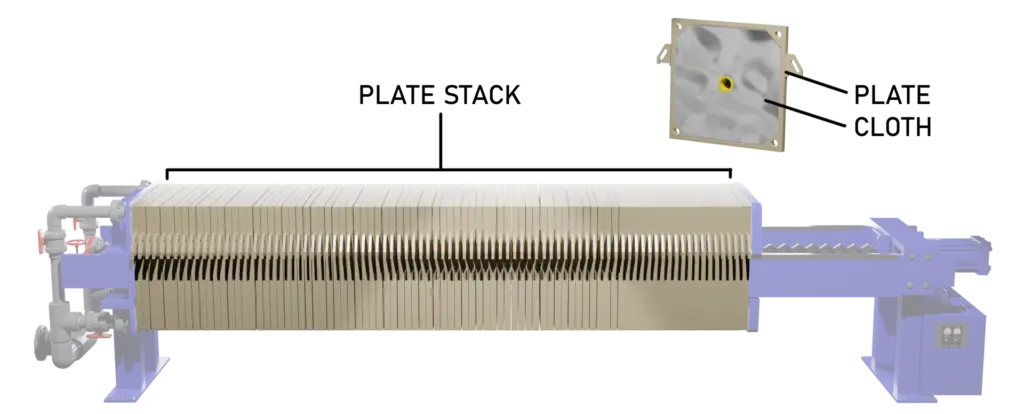

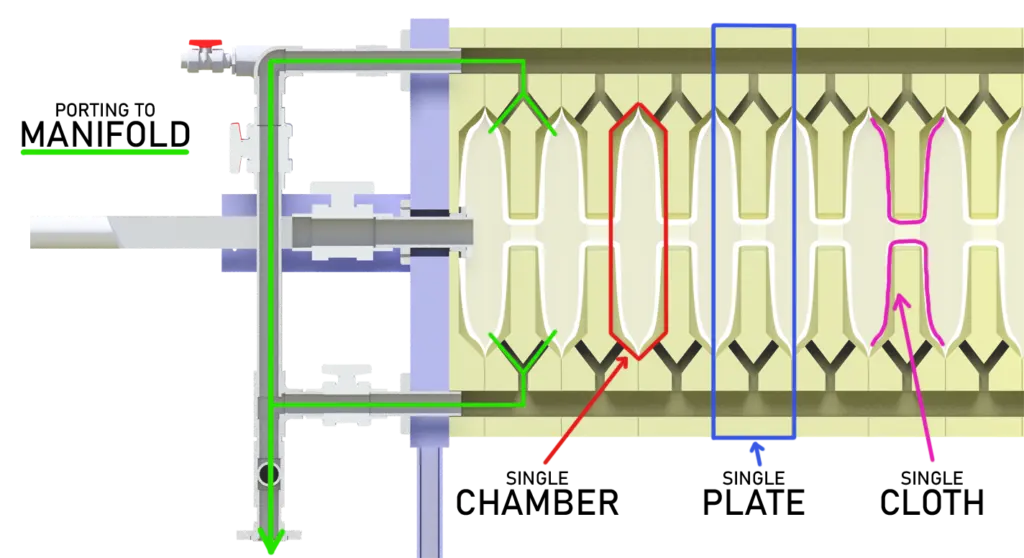

A filter press includes several core components. These include filter plates, filter cloths, a steel frame, hydraulics, and manifolds. Together, these parts drive consistent solid-liquid separation.

To get the best performance, extend equipment life and reduce downtime you must understand each component. In turn, that knowledge helps extend equipment life and reduce downtime.

Filter plates form the chambers where filtration takes place. Filter cloths are a critical component, as they act as the medium through which the filtrate passes while retaining the solids.

The hydraulic system is used to open and close the press, applying the necessary pressure during the filtration cycle. Multiple filter plates are clamped plates together within a steel frame.

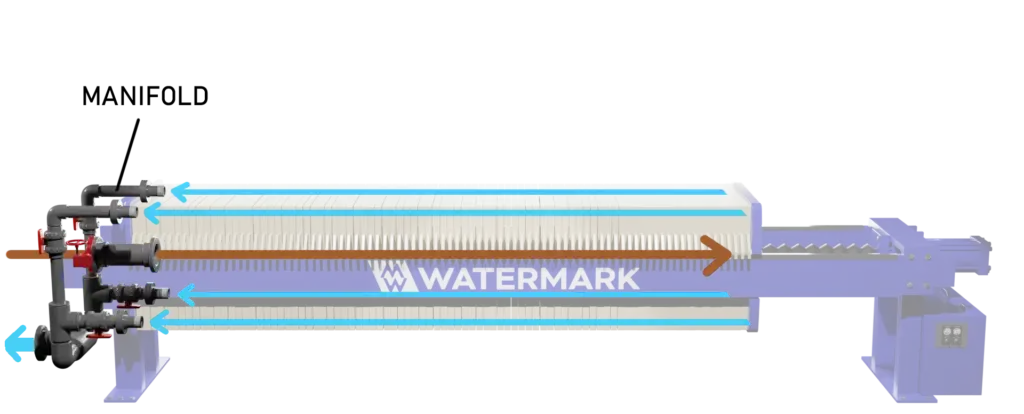

This plate stack creates a circuit for the liquid, beginning and ending at the manifold.

How Does a Filter Press Work?

How does it work? During the fill cycle, the system pumps slurry into the filter press. Solids then distribute evenly throughout each chamber. This process effectively separates the liquid from the solids.

Filter Cloths and Plates

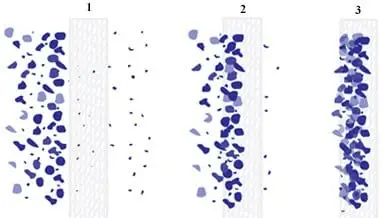

The filter cloth lies at the core of a filter press filtration system, separating liquid filtrate from suspended solid particles. Initially, fine particles may pass through (fig. 1). Subsequently, larger particles block the cloth’s openings and form a layer that improves filtration efficiency by narrowing the effective pore size (fig. 2). During the feed cycle, the press distributes solids evenly into each chamber. As pressure builds, they compact tightly, which enhances dewatering efficiency (fig. 3).

By the end of the filtration cycle, the filter press fills each chamber completely with dewatered filter cake. The system forms each chamber by clamping two filter plates together and enclosing the cavity in filter cloth. The steel frame holds and aligns the plates, creating a chamber system that defines the press’s total filtration capacity.

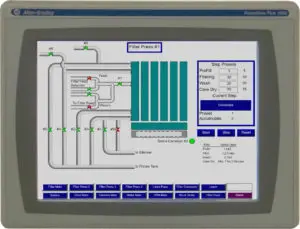

Manifold

After the liquid passes through the cloth barrier, the plates feature an inner porting system that delivers filtrate to the manifold. Once filling is complete, the operator adjusts the valves to end the cycle and to direct filtrate out through a single outlet.

When the filtration cycle ends, the follower retracts, and the operator can empty the press. The operator clamps the press to start a new batch.

Many high-capacity filter presses use fast-action automatic plate shifters to speed up cycle times. Manufacturers build some filter presses for fully automatic, 24-hour operation in harsh environments like mining and chemical processing.

Key Benefits of Filter Press Industrial Filtration

Produces high-clarity filtrate suitable for reuse or discharge

Achieves drier filter cake, reducing hauling and disposal costs

Handles high solids concentrations efficiently

Scales from manual to fully automated operation

Supports a wide range of industrial filtration applications

Types of Filter Presses

The most common types—plate and frame, recessed chamber, membrane, and automatic—each serve specific applications and operational needs by design.

- A plate and frame press uses alternating plates and frames clamped together to create a series of filtration chambers. Plate and frame presses work well in applications with low solids content and minimal filtration demands.

- Recessed chamber presses use recessed plates to form individual filtration chambers. In comparison, recessed chamber systems operate more efficiently and handle higher solids concentrations. For more info see differences between plate and frame and recessed chamber.

- Membrane presses incorporate flexible membranes within the plates to produce drier filter cakes and improve separation efficiency.

- Automatic presses support high-volume operations with minimal manual intervention.

Applications

Industries like surface finishing, chemical engineering, battery recycling, bioplastic production, mining, data centers, and food and beverage processing all integrate filter presses into their workflows.

Industry demands and application requirements guide filter press design decisions. Operating conditions further influence filtration capacity, chamber count, plate size, and material selection.

In addition, design options may include plate shifters, cloth washing system, drip trays, cake shields and safety light curtains. Because of these variables, engineers customize each filter press for the specific application.

Key design goals include filtration cycle time, desired cake dryness, and extended cloth life. Finally, automation preferences range from manual operation to fully automated plate shifting systems.

Why M.W. Watermark?

M.W. Watermark® manufactures industry-leading equipment for water and process filtration applications worldwide. Our team offers a wide selection of filter press types, capacities, parts, and accessories to suit different applications. Visit our Filter Presses product page to learn more. Use our custom designed filter press sizing calculator to find the right solution for your application.

Contact our filtration experts to discuss your filtration needs.