Filter Cake Discharge Options

M.W. Watermark® provides self-dumping cake hoppers (also known as a dumpsters), leg extensions and elevated platforms with discharge chutes to allow filter cake to be discharged directly to a drum or bulk bag, and integrated screw conveyors to transport the filter cake to single or multiple discharge locations.

- Description

- Photos

- Videos

HOPPERS & DUMPSTERS

M.W. Watermark® provides self-dumping cake hoppers (also known as a dumpsters) for easy handling of discharged solids. The hoppers are furnished with large ball bearing swivel-casters for easy positioning under the press, either manually or by lift truck. When filled, the operator picks up the hopper using a forklift and positions it over a larger container. It is emptied quickly and easily by pulling the spring-loaded self-dump pin. Our Filter Cake Dumpster Sizes and Accessories Sheet provides a list of filter cake dumpsters in a variety of sizes to fit the dimensions of your filter press.

LEG EXTENSIONS, CHUTES AND PLATFORMS

If you are using a smaller press, M.W. Watermark offers leg extensions and discharge chutes to allow filter cake to be discharged directly to a drum or bulk bag. The extended legs raise the press to allow room for one or more barrels to catch the filter cake when released from the press.

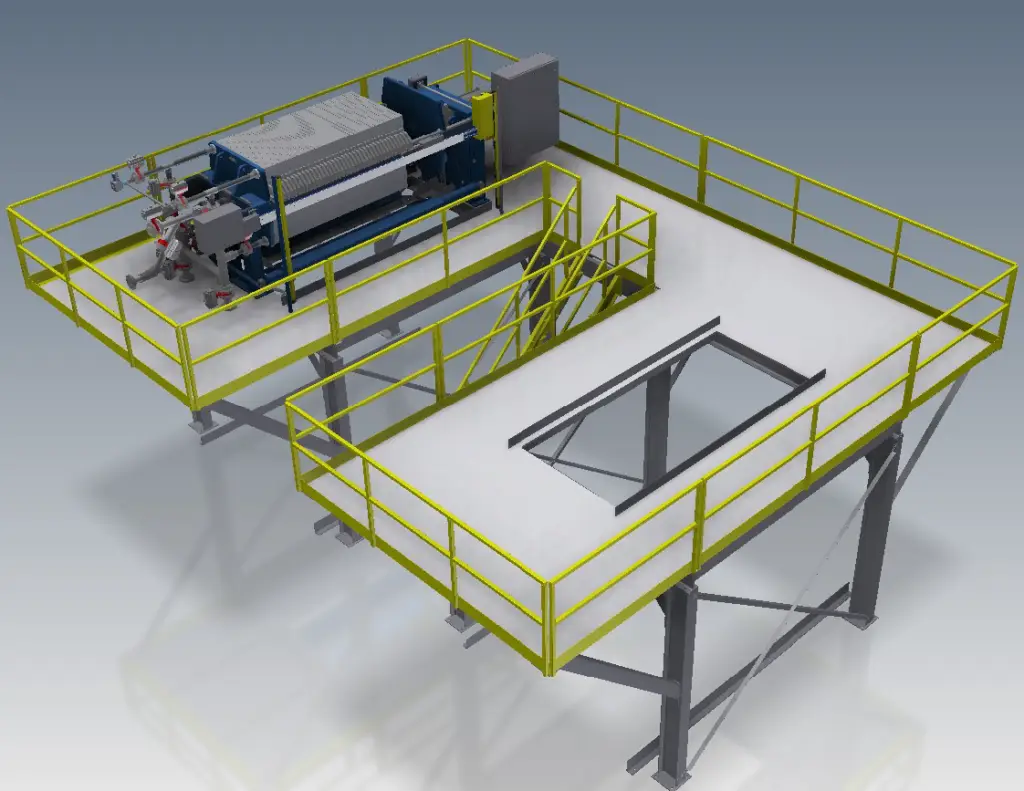

Larger filter presses can be equipped with an elevated platform that allows roll-off containers, bulk bags or dumpsters to be placed underneath. A “roll-off” platform can be very efficient when managing a large volume of filter cake, as the wheeled bins can be loaded onto a truck quickly and hauled away. Download our Filter Press Platforms brochure.

M.W. Watermark 1000mm Filter Press on a Roll-Off Platform – 3D Design Drawing and On-Site Installation Photos

BELT, SCREW, AND DRAG CONVEYORS

M.W. Watermark can supply integrated belt, screw or drag chain conveyors to transport the filter cake to one or more discharge locations. This can eliminate the need for a forklift or platform while minimizing operator time handling the filter cake. It can also provide the option of discharging to a truck/trailer to be hauled for disposal using an optional inclined conveyor. Discharge chutes are included, either in stainless steel or other materials, to direct the filter cake to the conveyor.

DRIP TRAYS (BOMB BAY DOORS)

The automatically actuated drip trays (also referred to as “bomb bay doors”) catch any filtrate that escapes from between the filter plates during filtration or when washing the plates and cloths. The trays are held in the horizontal sloped position during dewatering or cloth washing and rotated to the vertical position for cake discharge. Actuation of the trays is either by air or hydraulic cylinders. The trays slope to the non-operating side of the filter press, where the flow is directed to a launder. The launder can be piped for recycling, or to a drain depending on project requirements.

M.W. Watermark has a team of experts in-house that can work with you to design the best material handling system for your application. Contact us today to learn more.